This is my first GTR, its a 1996 Le Mans Limited. I purchased the car 2 years ago and have enjoyed every minute of ownership. I have decided I should start a build thread as the engine unfortunately has to be replaced and I have taken this as an opportunity to give the car a small make over. :smokin:

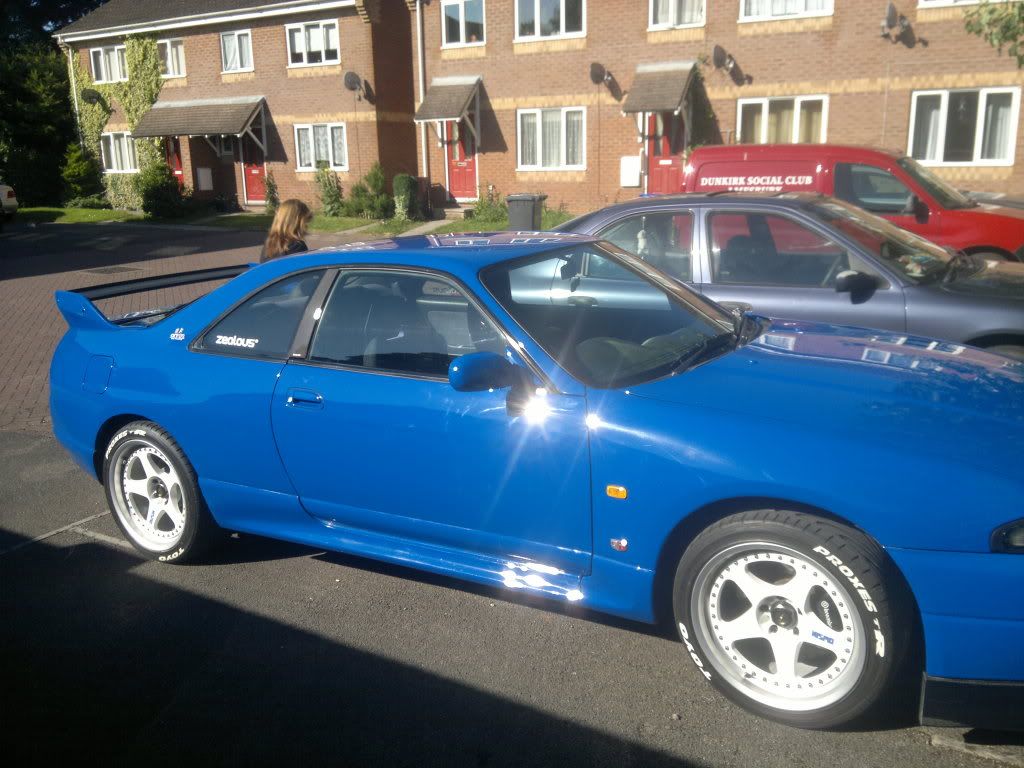

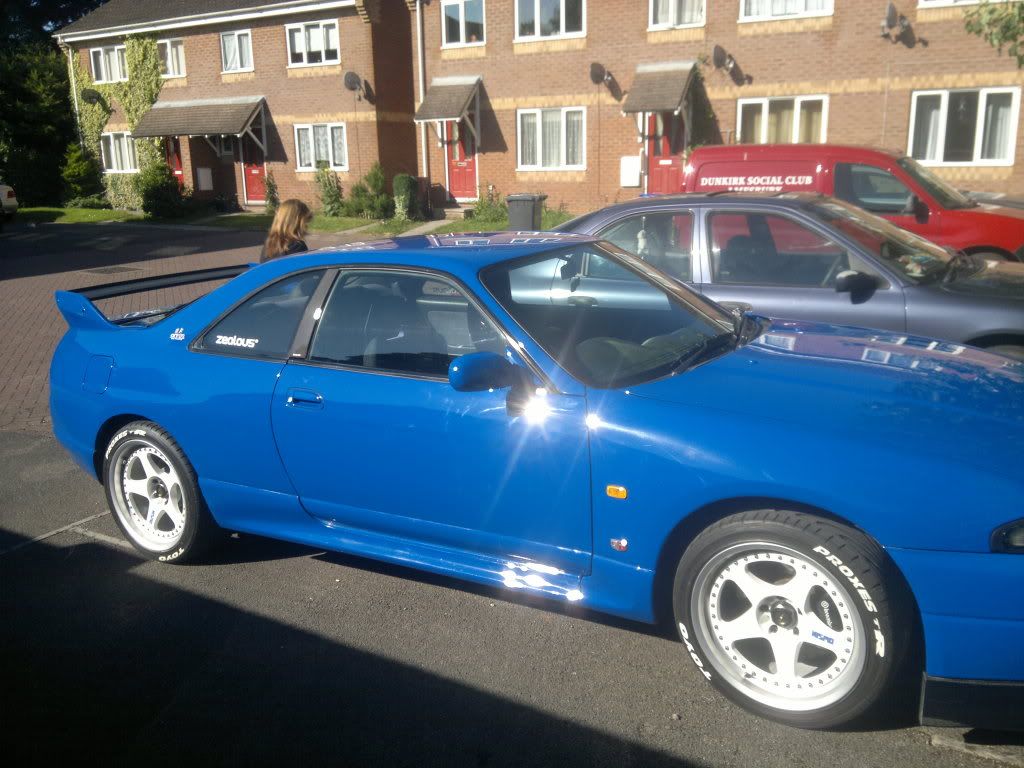

This is the car as I bought it

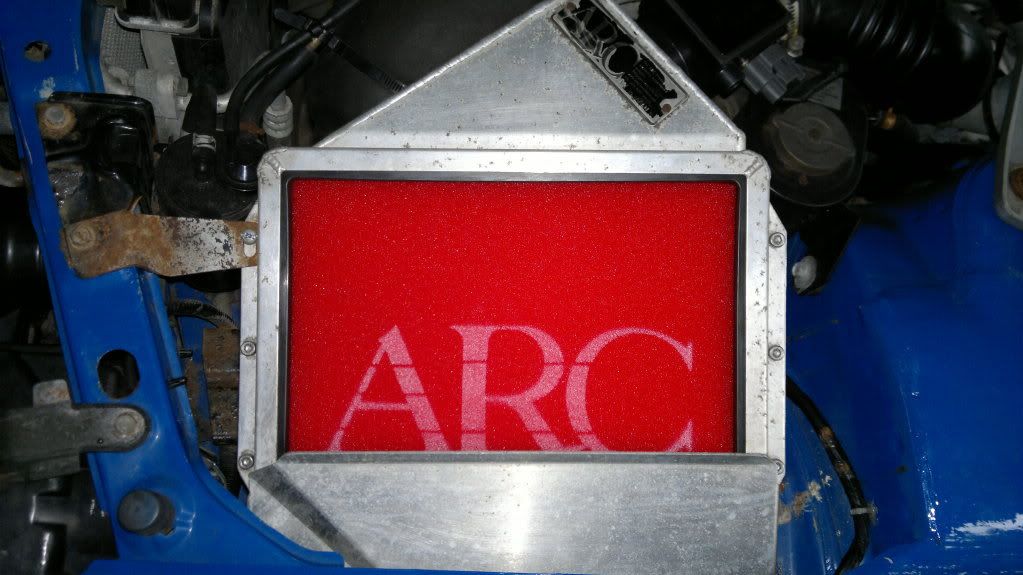

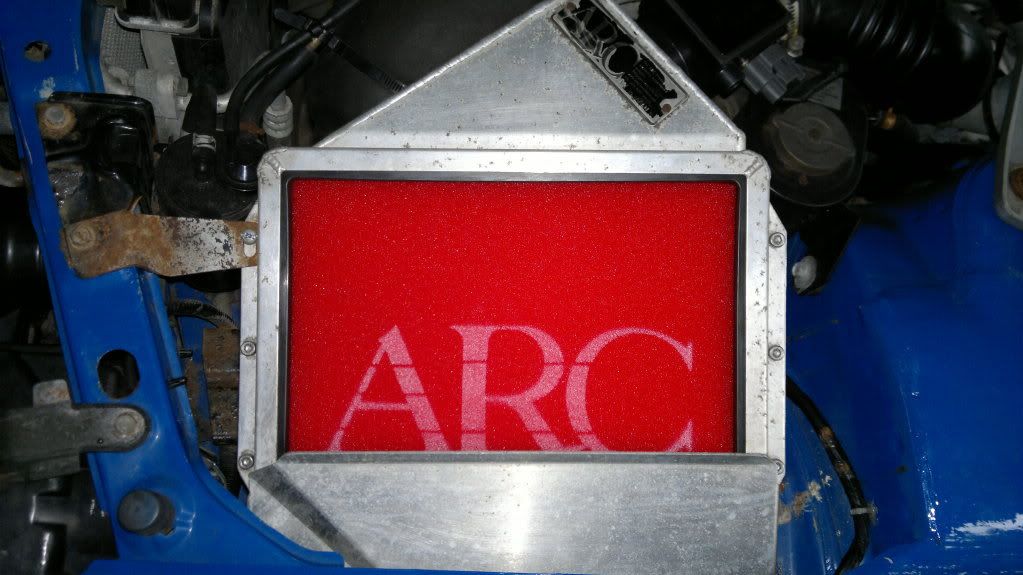

First job was replace the manky old air filters, they had definitely seen better days :chuckle:

nice new filters

Next the ebay exhaust had to go, it was rather LOUD!

So I needed something quieter as although it was amusing setting off every car alarm within 15 feet of the car at first it soon got tiresome. Enter the Kakimoto regu 06&R

As you can see its a very good looking exhaust and easily meets trackday noise tests. It is a very quiet exhaust, this does however come at a price. The price being flow, I believed it to be 3.5'' all the way through however I found that the reason its so quiet is because it has a restrictor in the back box. No bother off it went to have a new backbox fabricated keeping the Kakimoto tailpipe but without any restriction. Obviously it has become louder but is still within trackday limits. In my opinion it sounds even better than before.

Next came a cusco carbon strut brace, now the embarrassing engine bay shot.

This was then followed by Top Secret bonnet dampers

I had to get the nismo carbon spoiler blade carbon wrapped as the lacquer was peeling off and the carbon has become sun damaged beyond repair.

Around the same time I managed to find some LMGT1's in 18''x10'' I just had to get them refurbished in a colour more befitting of a Le Mans Limited

I have done a few other small mods to the car but as yet have no photos, I fitted a Nismo shortshift kit, Nismo clocks and gauges, Top secret oil cap, Nismo radiator, R35 GTR badge, Greddy radiator hose, carbon fibre radiator brackets and a carbon fibre front splitter. I'm sure that I have forgotten a couple of bits but I will no doubt cover anything I missed as the build continues and goes back together when the new engine goes in.

Thanks for reading thus far :wavey:

Will Small

This is the car as I bought it

First job was replace the manky old air filters, they had definitely seen better days :chuckle:

nice new filters

Next the ebay exhaust had to go, it was rather LOUD!

So I needed something quieter as although it was amusing setting off every car alarm within 15 feet of the car at first it soon got tiresome. Enter the Kakimoto regu 06&R

As you can see its a very good looking exhaust and easily meets trackday noise tests. It is a very quiet exhaust, this does however come at a price. The price being flow, I believed it to be 3.5'' all the way through however I found that the reason its so quiet is because it has a restrictor in the back box. No bother off it went to have a new backbox fabricated keeping the Kakimoto tailpipe but without any restriction. Obviously it has become louder but is still within trackday limits. In my opinion it sounds even better than before.

Next came a cusco carbon strut brace, now the embarrassing engine bay shot.

This was then followed by Top Secret bonnet dampers

I had to get the nismo carbon spoiler blade carbon wrapped as the lacquer was peeling off and the carbon has become sun damaged beyond repair.

Around the same time I managed to find some LMGT1's in 18''x10'' I just had to get them refurbished in a colour more befitting of a Le Mans Limited

I have done a few other small mods to the car but as yet have no photos, I fitted a Nismo shortshift kit, Nismo clocks and gauges, Top secret oil cap, Nismo radiator, R35 GTR badge, Greddy radiator hose, carbon fibre radiator brackets and a carbon fibre front splitter. I'm sure that I have forgotten a couple of bits but I will no doubt cover anything I missed as the build continues and goes back together when the new engine goes in.

Thanks for reading thus far :wavey:

Will Small